Duchess China were tasked to help the Grosvenor House Hotel to match existing ware shapes and printed designs. This was to replicate their banqueting products that were no longer available from a previous supplier.

The Duchess production and technical team set about selecting exisiting Duchess shapes, that matched the Grosvenor House Hotel's current tableware range. The team found that we hadn't cover for every piece of the range required, and therefore began manufacturing, modelling and developing new shapes that would match into the required range.

Fine Bone China is a durable vitrified body, we set about with guidance from our client reworking our flatware shapes incorporating a rolled edge onto the back of our plates. This extra durabilty to our china would help alleviate any of our client's fears that our product wouldn't stand up to the multiple every day rigors of a busy banqueting facility.

The next stage of production was for our design studio to produce fits, and style our products with the Grosvenor's existing white raised design, to each individual piece of a 20 plus item tableware range. Utilising our design team's many years of experience, each piece is given the attention to detail to match and look at where we could improve the products.

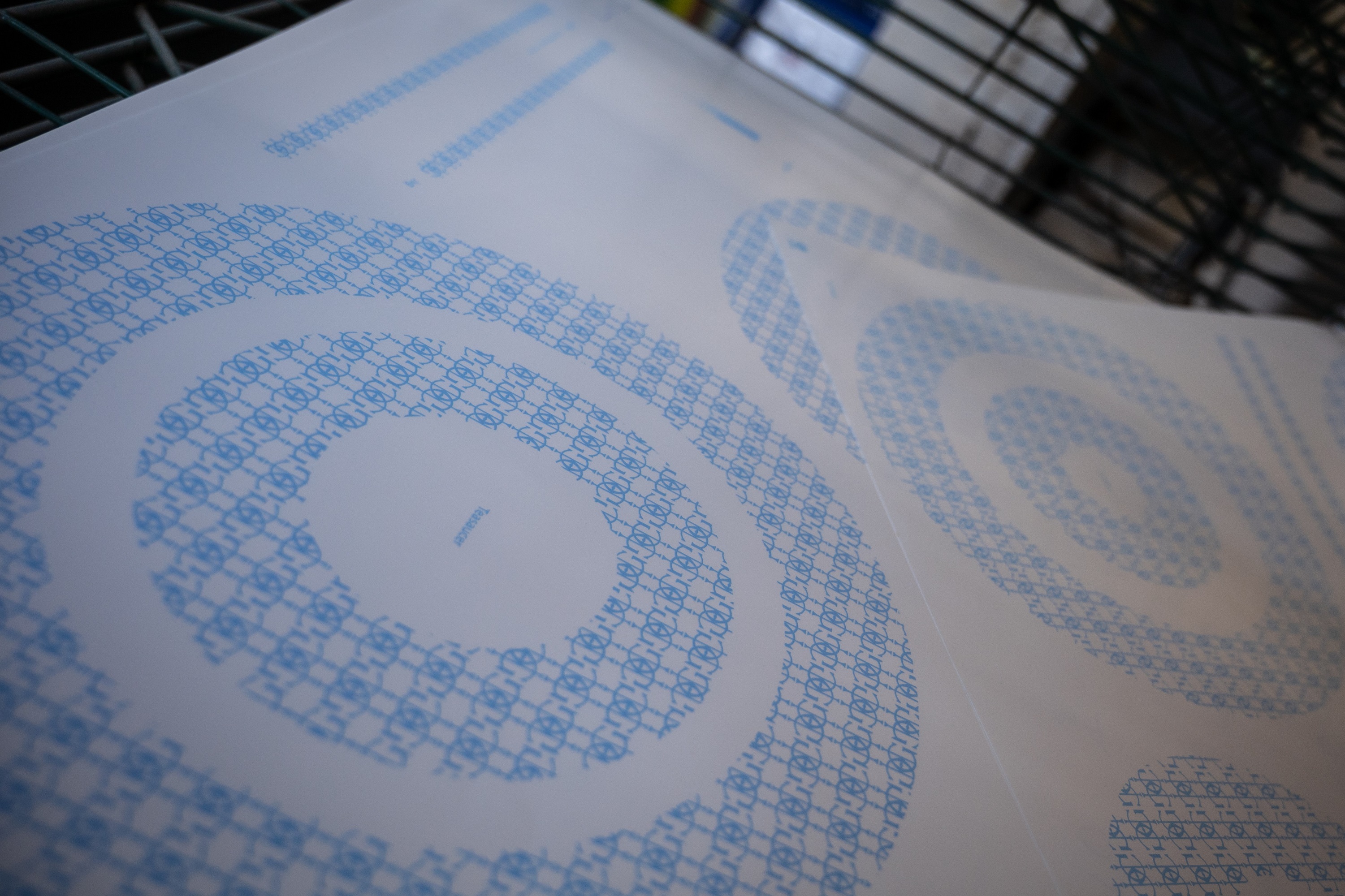

Our studio produced sheet layouts with ratios of products needed for our client's order. Simultaneously our printing department silk screen printed test colours, to make sure the colours and depth of the raised paste we were due to produce, matched the existing tableware. After sample test firing of a few items our quality control team were happy to approve.

Each individual design piece is silk screen multi printed onto the print layouts as setup by our design studio. Each colour of the three colours of the raised white design is printed through silk screens, the individual pigments are allowed to dry inbetween the next colour being added, the layers are built up until a final layer called a covercoat is over printed.

The printed designs were applied by hand to the various pieces. The next process stage is the firing of the decal onto the fine bone china. 850 degrees of heat work in a kiln over several hours fuses the printing colours, a finely ground glaze to the glaze of the plate making the decal permanent and scratch resistent. The fired pieces are selected and packed ready to despatch.

View Other Case Studies: The John Shaw Club | The Canvas Cafe |

have a project in mind ? send us an enquiry